In today’s competitive global market, manufacturing businesses face increasing pressure to demonstrate quality, reliability and environmental responsibility. For companies engaged in export sales, the challenge is even greater – overseas customers often have limited direct visibility of your operations, making third-party validation essential. This is where certification to ISO 9001:2015 (Quality Management Systems) and ISO 14001:2015 (Environmental Management Systems) becomes a powerful differentiator.

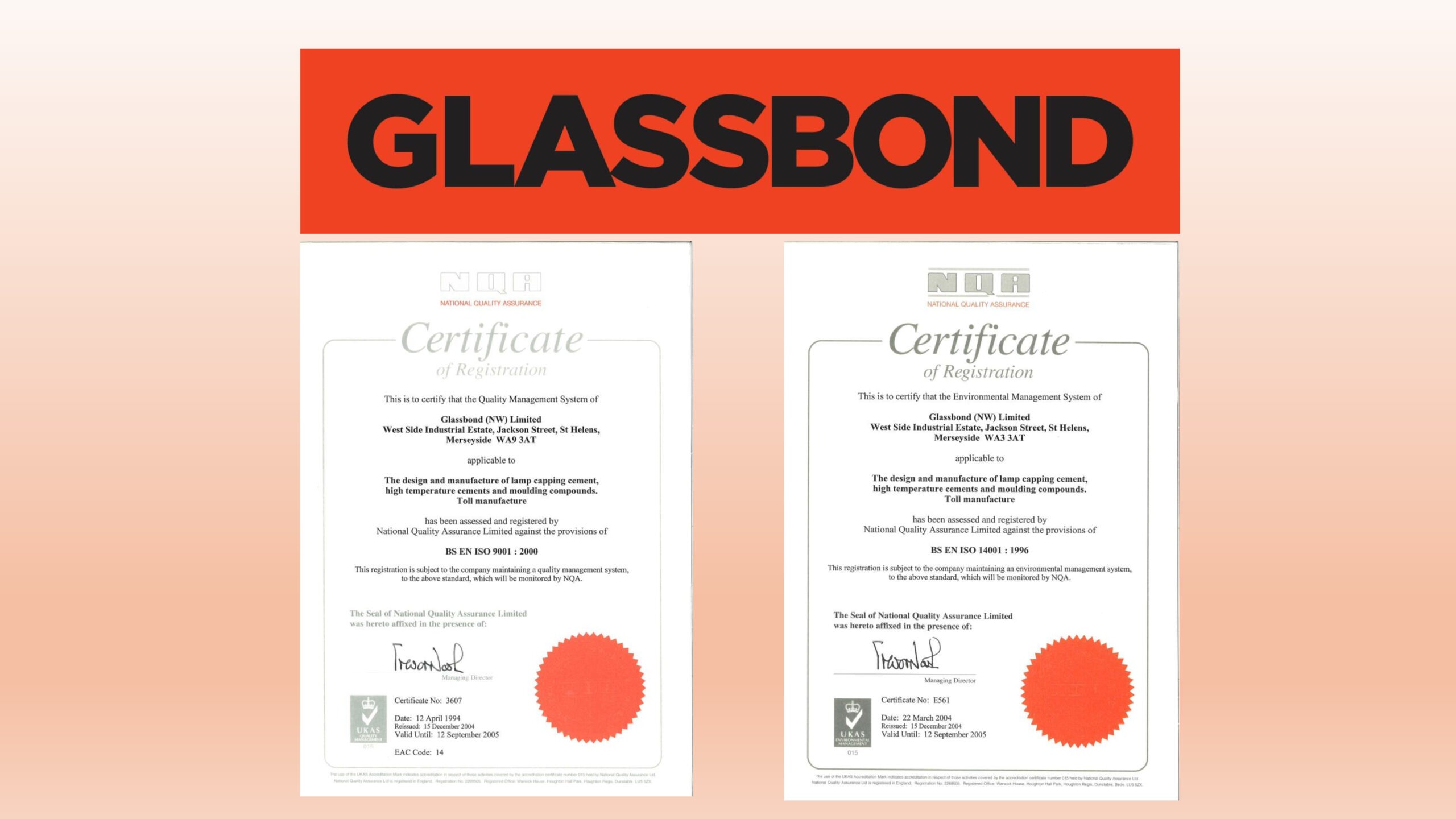

At Glassbond (NW) Ltd, we recognised these benefits decades ago, achieving ISO 9001 certification in 1994 and ISO 14001 certification in 2004. These standards are now fully embedded in our operations and continue to deliver tangible value to our business and customers worldwide.

Building Confidence in Export Markets

When selling into international markets, trust is everything. Buyers, distributors and end users want reassurance that:

- Your products are manufactured consistently and to agreed specifications

- Your operations comply with recognised quality and environmental benchmarks

- You actively manage risks and pursue continual improvement

ISO 9001:2015 and ISO 14001:2015 certification sends a clear message: this is a business that takes quality, compliance, and sustainability seriously. These standards are internationally recognised, which means our certification provides the same confidence whether we are dealing with customers in Europe, Asia, or around the globe.

The Benefits Inside the Business

While the external confidence certification provides is invaluable, the internal benefits are just as important. Both ISO standards help create robust systems and procedures that keep the business running smoothly and sustainably.

- ISO 9001:2015 focuses on ensuring consistent product quality through clear processes, responsibilities and performance measurement.

- ISO 14001:2015 ensures we identify, manage and reduce environmental impacts, considering the life cycle perspective — from sourcing raw materials through to end of life disposal.

Together, these standards drive compliance, risk management and identification of opportunities for improvement.

Continual Improvement – The Deming Cycle in Action

Central to both ISO 9001 and ISO 14001 is the Plan–Do–Check–Act (PDCA) cycle, also known as the Deming Cycle. This proven methodology ensures that:

- Plan – We set clear objectives and identify risks and opportunities

- Do – We implement the processes and controls to meet those objectives

- Check – We monitor and measure results against our targets

- Act – We make changes to improve performance and prevent future issues

This cycle keeps our management systems dynamic, ensuring we never stand still and are always looking for better ways to operate.

The Environmental Life Cycle Perspective

Under ISO 14001:2015, the life cycle perspective means assessing environmental impacts at every stage – from raw material acquisition to design, production, delivery, use and end of life. By doing so, we can:

- Minimise waste and resource use

- Reduce emissions and pollution risks

- Design products and processes that are more sustainable

This approach aligns with growing customer expectations for environmental responsibility, particularly in international markets where regulations and sustainability demands are tightening.

A Proven Commitment

Our early adoption of ISO standards reflects our belief in their long-term value. Since 1994 for ISO 9001 and 2004 for ISO 14001, we have seen first-hand how these frameworks help us:

- Maintain consistent quality for customers worldwide

- Demonstrate compliance to regulators and clients alike

- Drive efficiency and cost savings internally

- Meet and exceed environmental obligations

In short, certification has strengthened our reputation, opened new markets and ensured we are equipped to meet the challenges of modern manufacturing.

At Glassbond (NW) Ltd, we don’t just hold certificates – we live by the standards they represent. Our continued success in both domestic and export markets is proof that investing in quality and environmental management pays off for everyone: our customers, our employees and the planet.